Venus Rubbers is one of the most prominent and leading Industrial Rubber Roller Manufacturers in the industry, offering high-profile Rubber Rollers across Printing, Steel Plants, Metal Processing, Plastics, Paper, Textile, Food Processing, and Office Automation Equipment industries.

Roller Core Fabrication

The performance of Industrial Rubber Rollers depends on the rigid construction, minimal roll deflection, and balancing of the roll shell. The pipe is usually made of mild steel, cast iron, aluminium, or plastic in a pipe or solid form. Steel, or alloy steel, is predominantly used on end shafts, journals, and flanges. The welding, press, or shrink fitting method is used depending on the working condition of the Rubber Roller.

Grooving on the metal shell, degreasing, and grit blasting/linishing are done on shells to ensure good bonding. We, Venus Rubbers, offer after-sales support such as repair services for rolls, including journal welding and new bearing fitment, and static and dynamic roll balancing services. We follow various stringent manufacturing methods and techniques to engineer the roller core of the Industrial Rubber Roller to enhance durability and seamless performance in the long run.

Paper Industry Roller

The Paper Industry Rubber Roller is primarily used in the Dewatering, Sizing, Drying and Calendaring processes. A Wide range of Rollers, in a full range of hardness, are used to meet Chemical Resistance, High Temperatures, coefficient of friction and abrasion resistance requirements of the Papermaking Process.

View More

Textile Processing Roller

The Textile Industry utilizes Rubber Rollers in a range of hardness (45A – 100A) designed to squeeze water and or chemicals out of substrate/fabrics that are being manufactured. Nitrile, Natural Rubber, EPDM, CSM, XNBR, and HNBR are the common elastomers used in the manufacturing of Rubber Roller, specifically for Textile Processing.

View More

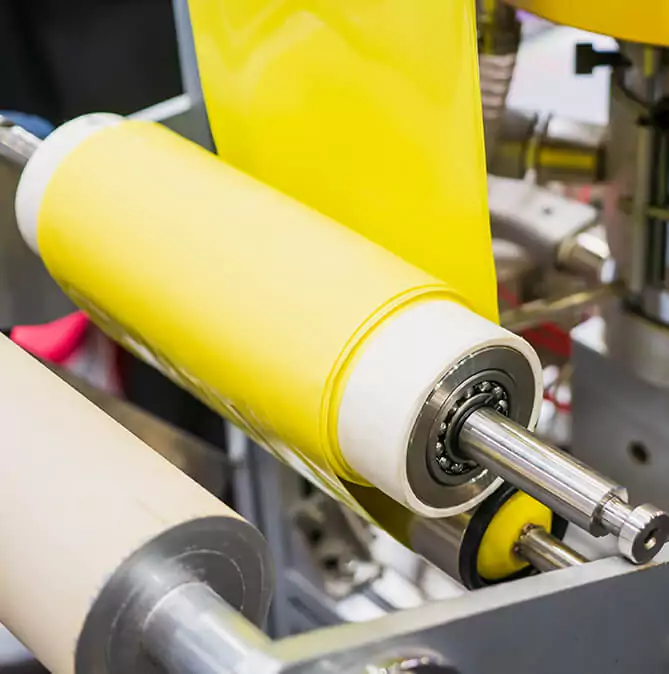

Thermal Lamination Roller

We manufacturer high performance Roller for Thermal Laminating Machines, exhibiting excellent heat resistance and release. HNBR, Silicone and heat resistant nitrile polymers are the core materials producing the Rubber Roller.

View More

Printing Industry Roller

We manufacture chemical resistant Rubber Roller to eliminate the chances of hardening and shrinking roller problems that generate during the process. The Printing Rubber Roller is featured with less heat buildup and hardness stability. Nitrile - PVC, Nitrile, EPDM and silicone are the common Rubber Materials used in the manufacturing of Rollers.

View MoreCover Compound and Roller Size

We, the Industrial Rubber Rollers Manufacturers, are highly proficient in producing rollers with covers made of nitrile, natural rubber, Neoprene, Hypalon, EPDM, and speciality compounds like high-release silicone and nitrile PVC materials to deliver efficient performance across different industries. At Venus Rubbers, we prefer automatic strip building and calendared sheet manufacturing methods to fabricate rubber roller cover compounds.

Our company has a state-of-the-art manufacturing facility to produce industrial rollers with rubber cover sizes ranging up to 1500 mm in diameter and 7000 mm in length. The quality of the rollers' covers is assured through the advanced vulcanization process done on SCADA controller autoclaves.

Rubber Grinding, Crowning and Grooving

We have the facilities to manufacture Industrial Rubber Rollers with blind drilling, grooving of Herringbone, diamond, fluted, and tailor-made groove patterns. CNC rubber grinding lathes are preferred for producing rollers with parallel, concave, and convex crowns. To elevate precision grinding and crowning, the Waldrich Roller Grinder is preferred in the manufacturing of rubber roller products.

We have a competitive edge in the industry as our manufacturing process involves stringent quality testing methods, such as rubber roller callipers, to ensure the rollers are within tolerances.